Category: Ferro Alloys

Ferro Alloys

Showing 33–48 of 61 results

-

Magnesium metal is very chemically active, it takes the place of hydrogen in boiling water and a great number of metals can be produced by thermic reduction of its salts and oxidized forms with magnesium.Used as a catalyst, magnesium promotes organic reactions of condensation, reduction, addition and dehalogenization. It was used for a long time …

-

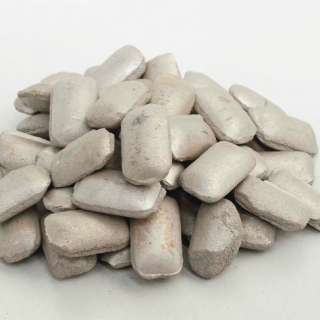

Metal manganese Briquette is pressed by the briquette machine with the raw material of electrolytic manganese metal powder, it contains Mn: 95-97% Size: 10-50mm Packing: in 1MT big bags Applications: Manganese ball is used in the field of steel smelting.In recent years, it has becomes the main manganese alloy additive in the production of high …

-

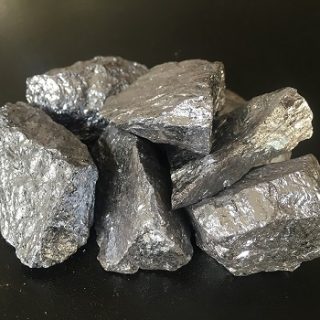

Manganese metal lump is made by remelting and ingot cast with the material of electrolytic manganese. And it contains Mn from 93% to 97%. Size: 10-50mm Packing: in 1MT big bags Characteristic:Comparing with electrolytic manganese flakes, it is more easy to be added and with less loss. Usage:Widely used in the produce of special steel …

-

Silicon powder special for refractory. Silicon powder,it is silver gray or dark gray powder with metallic luster.With the characteristic of high melting point, good heat resistance, high resistivity and high antioxidant effect, it is the basic raw material to refractiry industry,such as refractory castables,stopper rod.

-

Nitride ferro chrome is an alloy additive used primarily in the production of nitride stainless steel. Nitride ferro chrome consists mainly of nitrogen compounds such as Cr N, Cr2N and Fe4N. Effectively improves the strength and corrosion resistance of stainless steel.

-

Nitrided Vanadium is made of vanadium pentoxide, carbon powder, active agent and other raw materials, it mainly contains V and N, can replace the ferro vanadium in steelmaking. Nitrided Vanadium can save 20%-40% Vanadium compared with Ferro Vanadium under the same strength conditio. Nitrided Vanadium can reduce the fluctuation of steel properties. Nitrided Vanadium can …

-

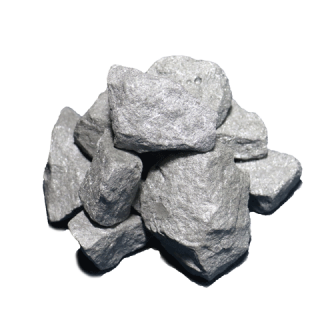

Rare earth magnesium ferrosilicon alloy refers to an alloy prepared by adding calcium, magnesium and rare earth to ferrosilicon. It is also called a magnesium alloy nodulizer. It is added as a nodulizer in the production of nodular cast iron to change flake graphite into nodular graphite. It can significantly improve the strength of cast …

-

Offgrade silicon is the low grade silicon metal, which contains Si 96%min. It can replace the silicon metal 553 to produce Aluminum, Also it can be used to replace the fesi in steel plant. Size: 10-50mm, 10-100mm or as per customers’ requirement. Packing:1MT/bag mainly used in steelmaking, aluminium alloy and so on It(Silicon 97) is …

-

Pig iron is a solid form of hot metal, obtained from iron ore or scrap recycling, and it is processed with blast furnace or electric arc furnace. Pig iron is used as a raw material for iron steel making and most of this material was imported. The term “pig iron” dates back to the time …

-

Radium is silvery, lustrous, soft, intensely radioactive. It readily oxidizes on exposure to air, turning from almost pure white to black. Radium is luminescent, corrodes in water to form radium hydroxide. Although is the heaviest member of the alkaline-earth group it is the most volatile.

-

Recarburizer, also know as carbon additive, carbon raiser. It is a product for increasing the carbon element (C).During the steel making process, various factors may cause the carbon content in the molten steel to decrease. This will affect the quality of the finished steel. So, steel mills usually purchase carbon reductants to cope with the …

-

Semi-coke is light black, characterized by high fixed carbon, high specific resistance, high chemical activity, low ash content, low sulfur and Low phosphorus It is wildly applied to such industries as chemical industry, metallurgic industry, and gas- making industry to produce calcium carbide, ferroalloy, ferrosilicon, silicon carbide, silicomanganese, fertilizer, etc. Semi coke is made from …

-

Silicon-calcium-barium-aluminum is the best deoxidizer and desulfurizer in barium alloys, which minimizes the oxygen in the steel, and the complex oxides containing calcium, barium, silicon, and aluminum formed at the same time easily float up from the molten steel. Pure molten steel improves the impact toughness and processing performance of steel.